Diamond cut Repairs?

For diamond cut repair, we meticulously restore and refine the surface of your wheels, preserving their original quality and appearance. Our specialised process includes precision machining to achieve a flawless, diamond – cut finish that enhances the aesthetic appeal of your wheels.

Detailed Steps of Our Diamond Cut Repair Process

Tyre Removal & Inspection

We carefully take the tyres off to access the entire alloy wheel. Each wheel and tyre gets a unique code for easy tracking during the repairs. Your valves and TPMS sensors are kept safe with your tyres.

Our experienced technicians conduct a thorough inspection of your alloy wheels to evaluate their condition . If any structural repairs such as straightening or welding are necessary , we will seek your approval. This step ensures that we can achieve the desired results while maintaining the structural integrity of the wheels.

With years of experience and a commitment to quality , Fusion wheels is your trusted partner for Diamond Cut Repairs. We understand the importance of preserving the integrity of your alloy wheels while enhancing their appearance.

Cleaning and Preparation

To ensure optimal results , the wheels are thoroughly cleaned and prepared for diamond cutting. This involves removing the existing coating from the surface of the wheels! Repair any dents and imperfections. Precise shot blasting to clean any dirt, corrosion or remain old coating. Masking up the hub and bolt holes, to keep them clean.

Powder Coating

The wheels are then electrostatically sprayed with a dry powder coating material. The electrostatic chage causes the powder particles to adhere uniformly to the surface of the wheels, creating a smooth and even coating. After the powder coating is applied , the wheels are transfered to a curing oven The heat from the oven causes the powder particles to melt and fuse togheter, forming a durable and protective coating.

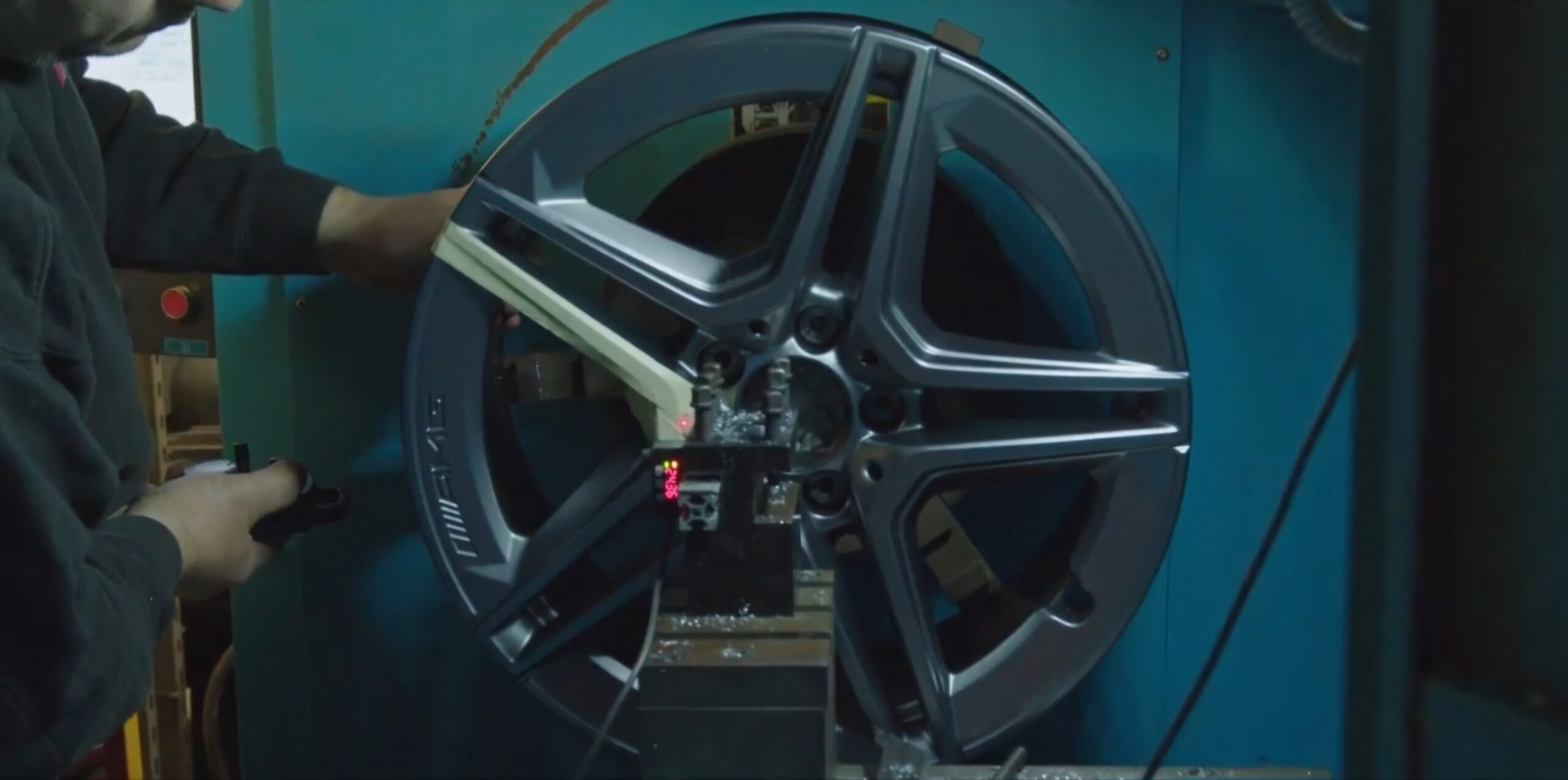

Diamond Cutting

After the powder coating has cooled , the wheels then are ready for diamond cutting! This process involves using CNC lathe to precisely remove a thin layer of the powder coating in specific patterns or designs, revealing the underlying metal surface. Diamond cutting adds a brilliant , reflective finish to the wheels , enhancing their appearance and visual appeal.

Preparation

The machine parts are thoroughly cleaned and prepared to remove any contaminants such as oil, grease or debris. This step ensures proper adhesion of the powder lacquer.

Powder Lacquering

The wheels are electrostatically sprayed with dry powder lacquer. The electrostatic charge causes the powder particles to adhere evenly to the surface of the wheels, covering them completely. After the lacquer is applied the wheels are transferred to a curing oven , where they are heated to specific temperatures. Once the curing process is complete , the wheels are allowed to cool down to room temperature. This ensures that the powder lacquer hardens properly and becomes durable and resistant to damage and ready for tyre fitting and balancing.

Contact Details

Warranty

Our diamond cut repair services come with 12 months warranty!

BOOK YOUR DIAMOND CUT REPAIR

Contact us today to schedule an appointment or request a quote for your wheels.